The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

2020-02-29 - Mainline Turnouts for Napa

Category RandallNow that I got the Napa yard fixed and working again, it’s time to use it for staging. Which means taking trains to and from the mainline..

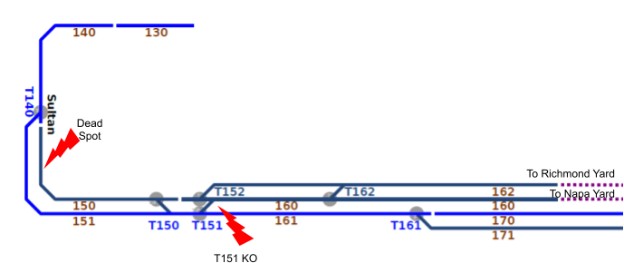

“Let’s look at the track schematic on how to go from the yard to the mainline. The “normal forward” direction on the mainline (when operators run in a continuous loop) on this schema is from right to left:”

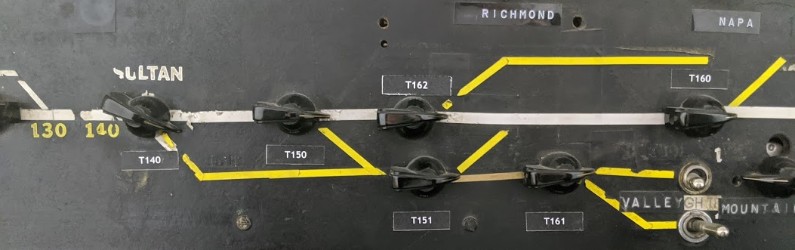

The turnout panel on the Valley is confusing and it’s never clear to me which toggle does what:

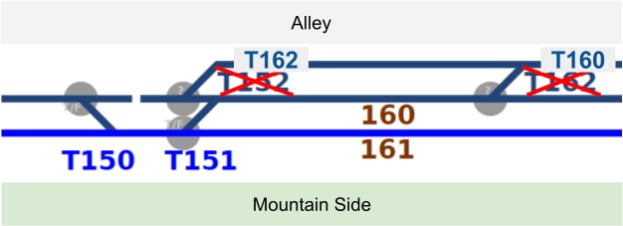

The layout has different types of turnout motors, which are annotated on my schema. The one above is hard to read, and zooming in reveals this (with turnout numbers corrected to match actual panels):

What this means:

- The gray circles indicate there is a rotary toggle on the corresponding panel.

- Both sides of the cross-overs are wired together.

- T150 is a dual Tortoise.

- T151 is a dual Fulgurex.

- T162 is a Fulgurex.

- T160 is a dual Tortoise.

(Edit: Updated schema to reflect proper turnout numbers; updated list above to reflect proper turnout motor type.)

Currently, only T150 works. T151 has one side not moving, and it is the one turnout I want to focus on. I don’t plan to use T152 for now. T162 is functional. They are all slow-motion motors, which means they are powered off the 11 V DC turnout bus using polarity-inverter DPDT rotary switches (actually most of them are 6P2T, 6 poles, 2 positions).

The main issue we have here is that the turnout controls are on the Valley Panel, which is on the opposite side of the room from these turnouts. An operator that wants to use these needs to walk all around the layout room, find the proper toggle, change it, and come back to the yard to switch its train, then back again across the room to reset the turnout. The area is not visible from the panel, and that means potentially one can leave the mainline turnouts thrown in the wrong position for a long time, not even knowing whether there’s a train coming or not.

My suggested fix is to disconnect the turnouts from the remove Valley Panel and instead add a small local panel to control these turnouts.

I’m about to do that, and I realize I have another opportunity I should take here: go directly with DCC control of these turnouts.

My original plan was to convert the whole Valley panel to using NCE Switch-8 DCC turnout control and still support fascia rotary switches via the NCE Button Board. That plan died when I found out that the NCE Button Board does not work well with non-momentary contacts, and that the Switch-8 cannot power the Fulgurex motors directly (too much current drawn). Both issues can be solved -- NCE sent me a firmware to reflash the Button Boards, and an NCE Relay board can be used to interface between the Switch-8 and the Fulgurex. Still it’s extra work that I could do without.

A few years ago when I was researching all this, I also got a Digitrax DS64 and a PR3 programmer. That was my “plan B” to compare it against the NCE. I haven’t used the DS64 on the layout yet, and this area would be a perfect test bed for it. The DS64 can supposedly trigger the Fulgurex directly, and it can supposedly support the rotary toggles.

So how do I use that DS64?