The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

2022-02-02 - Turnout T161 and a Philosophical Discussion on Having Too Much Track

Category RandallWe’re having a “dead spot” problem at turnout T161. Again. For the 3rd time.

I was going to ramble at length on the complexities of turnout designs and what causes them to short. Instead I’ve decided to skip that because https://dccwiki.com/Turnout has much better graphics, and better explanations. So please go read that.

One thing I do not know for sure is what kind of turnouts are installed at Randall. I should know. And document it.

The one thing I know is that pretty much all motorized turnouts use frog switching -- that is power to the frog is selected by contacts on the turnout motor.

Since it’s an old DC turnout with a common rail design, I strongly suspect we have power routing turnouts with non-isolating closure rails. See the graphics and explanation at https://dccwiki.com/Turnout#Non-Isolating for reference.

That’s easy to determine: do both points have the same polarity as the closed one and the frog (non-isolating, no gap between closure rail and live frog), or different polarity matching their stock rail (isolated, must have a gap between closure rail and live frog).

So, what’s the problem, doc?

Anyhow for turnout T161, I had identified an issue with the Fulgurex a while ago: the live frog is powered by a contact on the Fulgurex, that changes between rail A or B based on the position of the turnout. With age / dust / oxidation, there was a detectable resistance, enough to significantly affect the voltage at the frog and basically stop some engines. The solution back then was to swap the Fulgurex for another one with good contacts. Also a bit of contact cleaner can help, to some extent. Apparently that solution only lasted for 2 years.

There are two more permanent solutions. The first obvious one is to replace the turnout motor with a Tortoise. However that’s easier said than done as the location is really hard to access. There are 4 tracks meeting there at different vertical points and it’s basically impossible to stand anywhere at arm’s length to the actual turnout motor.

The second obvious solution is to stop using that turnout. And by that I mean leave the turnout in place, but disconnect it so that it cannot throw, and hardwire the frog to the desired location. I have done that in a couple other places for sidings we’ll never use. And when reflecting on that, I came to this realization:

We have too much track on this layout.

Or more exactly, there’s a mismatch between the layout -- as it has been originally designed -- and the way we use it right now.

This is a great example of the problem: the T161 turnout opens the single-track mainline to a siding. After this turnout, we have blocks B170 (mainline) and B171 (siding). The reality is that we never use that siding. Back in 2018, I spent quite some time cleaning both tracks and ensuring they both worked fine. Yet since, it has seen no operation that I know of. And I can’t blame the Saturday Operators for that -- this siding is in the back of the layout, one the other side of the control panel. It’s quite frankly a pain to use. As indicated above, the siding is not reachable by any human, so it’s not even a good place to spot a train to adjust its cars. And if a train gets stuck on the siding, there’s no way to reach it from the top, even with a reacher pole hook. It’s quite time consuming to go crawl under the layout and blindly try to adjust anything there from below. So basically this siding fails as a usable siding.

And there are many other sidings on this layout that are unusable, either because they are not functional or are simply inconvenient. Let’s go around the track (to follow along, open the Track Map from here):

- B372 is the Upper Summit siding. Not functional: the turnout motor leading to that track doesn’t work, and it’s disconnected anyway. I even blocked it with a little passenger station since the automation train stops there.

- B371 is the Lower Summit siding. Functional. I cleaned it back in 2018 and since then it has never been used.

- B401 is the Walong siding after the shed on the mountain. I’ve never seen it in use, ever, even when the club ran back in 2014~2015. The turnout motor didn't even have a throw rod last time I checked it out.

- B431 is the outer siding on the Tehachapi loop. Likely functional -- last used/cleaned in 2018. Not a fun place to derail or get stuck, though.

- B462/B171 is that siding in the back that leads to T161, the problematic turnout in question. I cleaned it back in 2018 and since then it has never been used.

- B151 is the Sultan siding. Used to be functional and used. Currently has a phantom dead spot (likely a bad solder) that I plan to address at some point.

- T130 is the turnout diverging the mainline towards the Fairfield Industrial City. This one had a bad connection in the turnout motor’s contacts, and I fixed it by bypassing the contacts. The frog is hardwired for straight running.

- B121 is the Fairfield passenger station siding. Not functional. It’s an easy place to derail. Turnout at the station doesn’t currently throw, and the turnout going back to mainline at Lodi has a broken point.

- B91 and B81 are sidings around Fairfield at “Timber Creek Jct”. These are functional and I’m trying to encourage operators to use them more. They are also great places to stop trains for visitors to enjoy. However it would be a pain to derail or get stuck there.

- B51 is a siding in the return tunnel before going back to the Stockton Station. Likely functional -- last used/cleaned in 2018. No operator visibility, being in a tunnel.

As a side note: the astute reader will note the repeated pattern of “it’s a pain to derail there”... Unfortunately that covers something like half or more of this layout. A lot of these sidings are impossible to reach at arm’s length or even with a reacher pole hook. On some of them, we can crawl under the layout and hope to get nearby using one of the access holes.

So how and why did we get there? There are two reasons.

First, there’s a natural tendency for anyone building a track plan to cram as much track as possible in there. I’ve done it. Everyone who has started a layout has done it. On paper, the track is “free” and why waste space? More track means more impressive. Till one builds it and it’s an extra expense, and extra maintenance, etc.

Second, I firmly believe this layout was built to mimic the SP “single track mainline with passing sidings”, so there’s some legitimacy right there, and it was obviously designed to run with dispatchers. If one were to do operations by having dispatchers stationed at the two main panels (the “control towers”), then it doesn’t matter if a piece of track is on the other side of the layout. The train conductor likely has a track warrant and a time table, and then asks the dispatcher to throw the turnouts to enter and leave a siding. That allows to coordinate meets with opposite trains, exactly like on the real SP.

Except… that’s not how we run with DCC these days. Thus my saying there’s a mismatch between the layout design and the current usage pattern. The current pattern is to use the mainline as a single-direction track, essentially a super fancy 4x8 oval loop design. In this context, operators don’t need sidings. In fact they don’t even expect other operators to stop at all, which incidentally means any issue quickly becomes a wreck on a wreck at the smallest gap in communication.

The conclusion is that we should adjust the layout to fit the current usage. If a siding is not useful, there’s little point in maintaining it. Concretely, I suggest we disconnect the turnout(s) (either one or both sides of the siding) and wire the live frog for normal/straight running. The nice thing with this is that it can all be done just at the block terminal under the turnout. It’s easy and accessible, but more importantly if we label it correctly it’s 100% reversible. We are not sacrificing anything, it’s not permanent, and we can change our mind later.

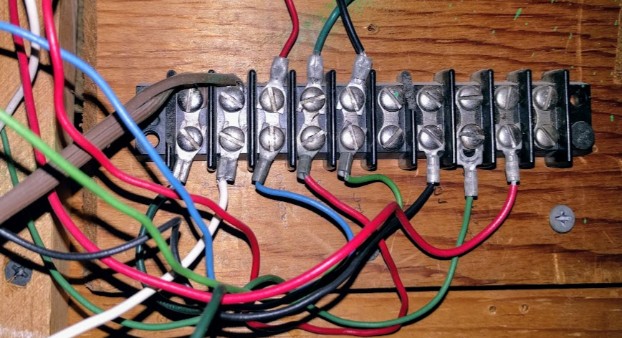

Original terminal block for this turnout

Top of the terminal connects to the turnout toggle (brown house wire) and to the track.

Bottom of the terminal connects to the Fulgurex contacts.

For a description of the terminal block, read the 2018-12-12 T161 Repair Report.

Changes to be made at T161:

- The 3 top wires go to the track (Red = Rail A, Green = Frog, Black = Rail B). To hardwire the frog, connect the middle top green to either red or black depending on the position of the turnout.

- Disconnect the bottom left-side white / black wires which power the Fulgurex. This ensures it will not throw.

- Label these wires so that we know how to rewire them later.

- Label the turnout toggle on the Valley Panel to make it clear this turnout is deactivated.

Decide if we want to do the same on the other side, or keep the siding as a possible “dead end”.