The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

2025-08-03 - Randall Repairs: Summit Mainline Track and Turnout T370

Category RandallAffected |

Summit Mainline Track, Turnout T370. |

Description |

Gap and dip in the mainline track (which was held using hot glue!) |

Summary Fix |

Removed the obsolete turnout T370, replaced 4 feet of mainline track. |

Description of Issue

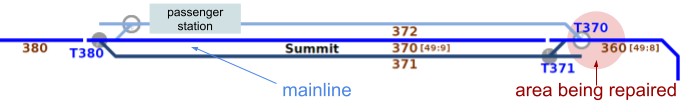

The top of the mountain is an area known as “Summit”. The mainline has two sidings around the mainline. The siding B372 has never been used and both turnouts on either side are non-functional. It now contains a little station which is where the Automation Passenger Train stops and reverses. The siding B371 used to work fine, and although it hasn’t been used in a while, we may restore it at some point.

A view of the mainline track to be replaced -- from before the bridge up to the first turnout before the signal bridge.

Just before turnout T370, the mainline track was of sub-par quality. There was a couple millimeter gap in the track, and it was held in place using hot glue. Once in a while we would get derailments there, and at some point we got a dead spot, and I did some repairs back in 2018.

Turnout T370 had been the cause of derailments in the past and I had spiked it. Anyhow, the Fulgurex motor underneath was disconnected. Here’s how I left the track back in 2018, and you can see the poor track alignment, and that’s when I was amazed to find the track was held using some hot glue:

Back in 2018 when I soldered that bonding wire to fix the track continuity problem, I was surprised when the part below the solder started melting and that’s how I discovered that this was held using hot glue. It must have been done a long time as it had blended with the rest of the scenery. Anyhow, as I wrote back then, that bonding wire was supposed to be a temporary fix. And now we’re finally circling back and taking care of it.

Description of Fix

Orion did all the work related to this. My role here was mostly support, organization, and being “the voice of reason”. We both decided we didn’t really need turnout T370. It was spiked, and we had no intention of using the siding at B372 since now it holds the Summit station. However I wanted to keep the other siding as it may be nice to restore it later. To fix the track, Orion suggested simply removing all the track from the turnout up to the next junction point of the flex track, on the other side of the bridge.

Based on the preliminary discussion, we checked we had all the materials needed for this work. Of concern was the bridge: as we were going to remove the track over the bridge, there was a possibility that we might damage the structure, and I just wanted to check that we could easily replace it if needed.

A quick check revealed that the bridge is Walthers Cornerstone "single track railroad truss bridge kit" Part # 933-3185. That’s easy to replace if needed.

Orion preparing to remove the old track.

A bit of isopropyl alcohol made quick work of loosening the scenery holding the track.

Orion desoldering turnout T370.

In a short time, Orion had the turnout removed. That surprisingly went smoother than expected!

Orion desoldering the track joiners on the other side of the bridge.

We’re close to the basement ceiling here so there isn’t a lot of headroom to work.

With a bit of persuasion, Orion got the track desoldered neatly.

Now we had the track removed. It was time to install new track after cleaning up the area and preparing it.

Wood shims and cardboard pieces were used to level the approaches on both sides of the bridge.

Orion first soldered the new flex track with new rail joiners on the B360 side.

A caboose and my trusty NMRA “Mark IVb” HO Gauge were used to verify track gauge, level, and alignment.

The new track is held in place with glue. I didn’t find the usual white glue around so instead I got some Tidebond II glue from the wood workshop. I believe it also softens with isopropyl alcohol later if we need to work on the track again.

Orion soldering the flex track where the old turnout used to be.

An attempt was made to use “transition joiners” between the code 83 and the code 100 track at this junction. That didn’t go well, and after a lot of time spent on that failure, Orion went back to regular universal joiners.

Testing the new track junctions.

The scene after cleanup.

Running the automation train to test the new mainline track.

Orion added a track bumper on the end of the siding.

We ran the Automated Passenger train several times on that new section of the mainline. Since the automated train runs as a shuttle, it runs both in forward and reverse on this part of the track and it’s very prone to derailment when there are alignment or defects in the track, making it a perfect test. This was, however, a fairly slow and finicky process.

Not detailed above, various pieces of wood or cardboard were used to shim the track and level it on the right side of the bridge as needed. I also won’t go into the cleanup details -- from cleaning up solder joints to filing them, vacuuming the area here and below, running the track cleaning train, etc.

Orion wanted to then immediately ballast the track. That’s not an area that museum visitors can see up close, so I’m not too concerned about the look. However I see some value in that as it will hold the new flex track in place. That said I insisted we do that another day -- it was getting late and I didn’t want us to do a rush job and then close the layout without having a good chance to test our work, not to mention cleaning everything again. Later I realized another good reason is that we can run the mainline as-is for a little while, and it will make it easier to do any correction if necessary. Then once we know we have good track work, Orion can ballast it.

Fix time: 6 hours.